BASED IN OSLO, Norway, The Norwegian EPD Foundation (EPD-Norway) helps businesses to communicate the environmental performance of their products through verified and understandable environmental declarations. The program ensures that the development of EPDs (Environmental Product Declarations) for all types of products are carried out in accordance with the requirements set out in ISO 14025, ISO 21930 and associated industry standards (EN 15804 for Building Materials). EPD-Norway cooperates with other EPD program operators around the world that also follow ISO 14025. Almost every European country has at least one EPD program operator. Many other countries around the world have equivalent EPD program operators.

What is an EPD?

Recognised in Norway and internationally, an EPD provides a standard way of declaring the impacts of manufacturing and using products through Life Cycle Assessment (LCA). An EPD is a concise document that summarises the environmental profile of a component, finished product or service in a standardised and objective way. It is created on the basis of an LCA according to ISO 14040-14044. These standardised methods ensure that environmental information within the same product category can be compared from product to product, regardless of region or country.

Since 2015, Håkon Hauan has been Managing Director of EPD-Norway. He comments: “I’m not an engineer. I studied International Economics and Administration at the Norwegian Business School in Oslo. From 1992, I worked as Director for Agfa Gevaert and CEO for Philips Norway. I also worked abroad for many years, including working for the Norwegian Government as CEO for Innovation in Spain, where I was responsible for environmental [EEA] grants and projects within Renewable Energy and the Environment. This role and my interest in the environment ultimately led me to apply for a position at EPD-Norway.”

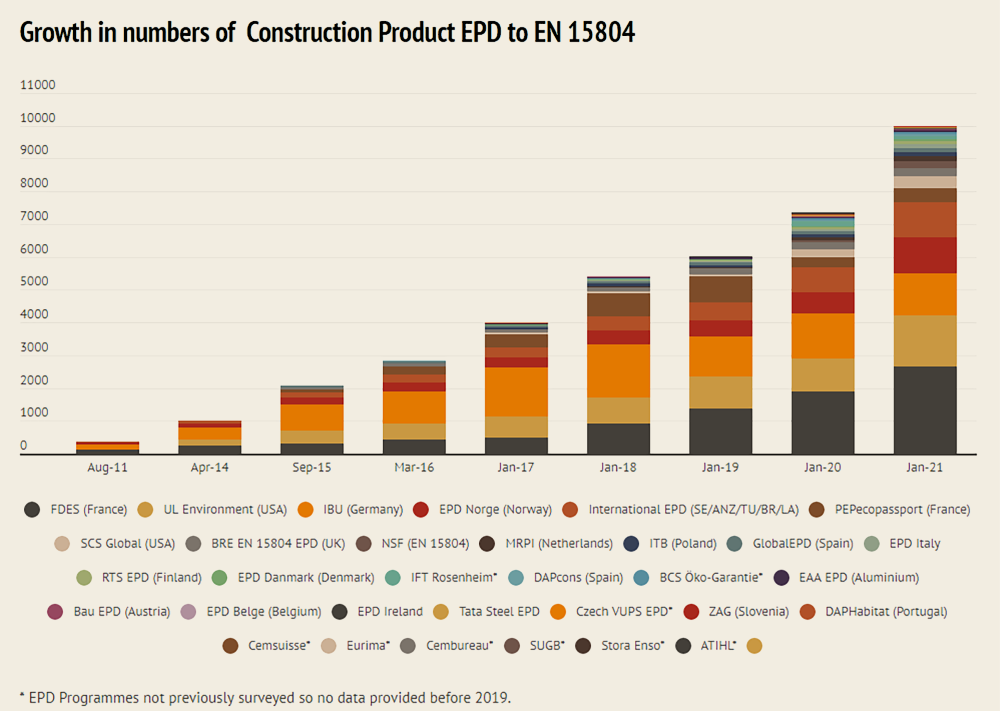

EPD-Norway is a type III environmental declaration program operator under ISO 14025. The program has established a system for verification, registration and publication of EPDs, as well as the maintenance of registers for EPD and PCR (Product Category Rules). EPD-Norway is a co-founder and member of the ECO Platform, a not-for-profit organisation that aims to harmonise the development of the use of EN 15804 in EPDs for contruction materials. Håkon was recently appointed as President of the ECO Platform.

Who should have an EPD?

The target audience for EPD applications is primarily Business-to-Business (B2B) but does not exclude B2C (Business-to-Consumers). To date, most EPD applications have come from the Building & Construction Industry – the biggest contributor to greenhouse gas emissions but also the sector with the greatest potential to reduce carbon emissions – with applications also coming from other industry sectors. Lighting, for example, comes under the ‘Building Materials’ category.

As Håkon Hauan states: “The purpose of an EPD is to enable the customer to compare the environmental profile and make an assessment and choice based on the environmental declaration. Anything from office furniture, glass and concrete used in a building project, to lighting, roofing, aluminium and asphalt, can be environmentally declared. The key is that an EPD is independently verified to ensure objectivity, comparability and credibility.”

,(0.5523437,0.4285714,0.8609375,0.8571429)&format=jpg)

,(0.5,0.3041667,1,0.55)&format=jpg)